The Smarter Guide to Jib Cranes: Specification, Selection & Setup

Your Guide to Jib Cranes – Expert Support from ULS Lifting

Your Guide to Jib Cranes – Smarter Lifting Starts Here

Choosing the right jib crane isn’t just about picking a boom length and bolting it to the floor. Even seasoned engineers and operations managers can find themselves working around a setup that doesn’t quite fit - whether it’s a misjudged rotation range, the wrong hoist type, or floor conditions that weren’t factored in from the start.

At ULS Lifting, we’ve helped hundreds of teams cut through complexity. Whether you're replacing a worn-out wall-mounted unit, upgrading to electric hoist control, or expanding into a new bay, we combine practical expertise with tailored solutions and ensure that installation is never an afterthought.

This guide brings together everything you need to make an informed decision, with expert advice on specification, mounting, compliance, and whether refurbished or brand-new is the smarter investment for your site.

What Is a Jib Crane?

Whether you call it a swing jib, slewing arm, wall jib, or simply a workshop crane, a jib crane is a compact, fixed lifting system designed for repetitive, localised lifting tasks.

Most models consist of a horizontal arm (or boom) that slews (swings) from left to right from a central position. Can be mounted on top of an upright pillar or mounted onto a column, or fixed directly to a wall. A hoist or vacuum lifter travels along the arm, allowing loads to be raised and repositioned within a defined working radius.

You’ll typically find jib cranes in:

- Machine shops and fabrication bays

- Loading docks and warehouse stations

- Vehicle maintenance workshops

- Manufacturing production lines

They're ideal when you need consistent lifting operations in a defined area, especially where overhead jib cranes can't be used.

Common alternate terms include:

- Swing arm crane

- Slew jib/slewing crane

- Wall-mounted crane

- Freestanding pillar crane

- Workshop crane

- Small industrial crane

If you're unsure what type you're working with, or what it's officially called, you're not alone. This guide will walk through the main types and help you match the name to the right specification.

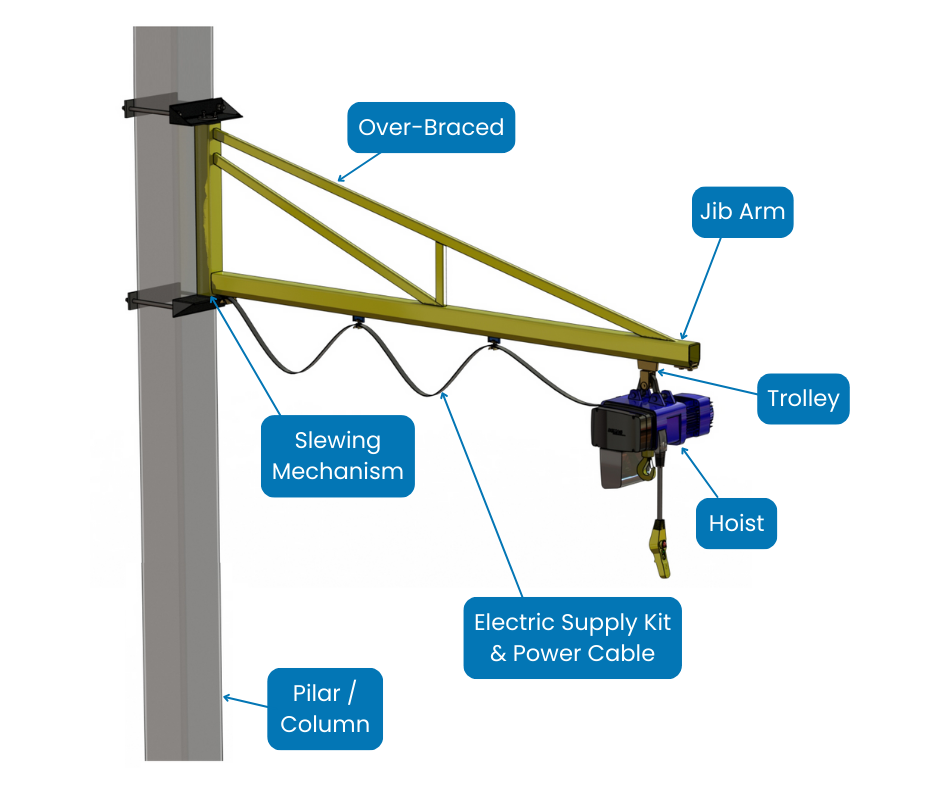

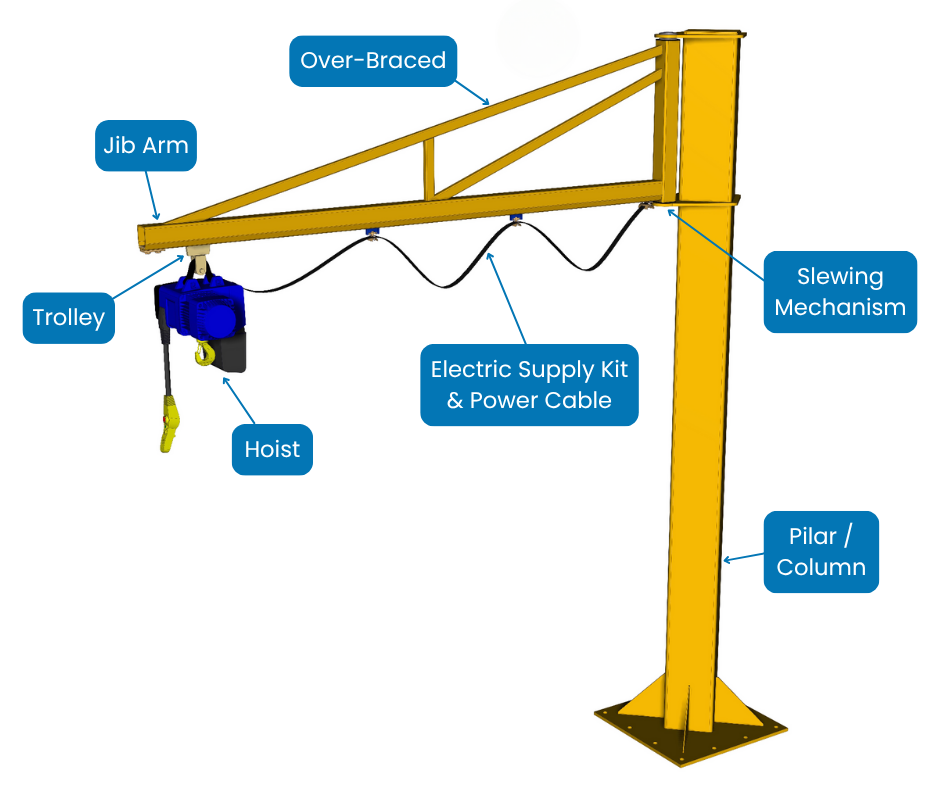

Key Components of a Jib Crane

Unsure what the parts of a jib crane do? Let’s break it down:

- Arm (Boom): The part that does the heavy lifting. This horizontal beam carries your load via the hoist.

- Wall or Column: The strong vertical support that keeps everything grounded. Mounted to a wall, column, or floor, depending on your setup.

- Rotation System: Allows the jib arm to swing into position. Available in manual or powered operation, with rotation from 180° up to 360° depending on your needs.

- Hoist: The lifting muscle of your crane, manual, electric, or pneumatic, tailored to suit your operation.

- Trolley (if applicable): Available in manual or powered operation, it lets the hoist glide smoothly along the boom to position your load precisely.

Jib Spec Sheets Aren’t the Whole Story

On paper, choosing a jib crane looks simple: define your safe working load, select a boom length, decide on a hoist type - job done. But in practice, getting the right jib crane means understanding how your workspace behaves when people, materials, and processes come into play.

- Crane selection isn’t just a technical exercise. It’s an operational one.

- A few common oversights we see:

- Arm swing overlapping racking or doorways

- Rotation limits often get overlooked when site layout changes after installation.

- Height of lift that doesn’t match the load path

- If the hoist can’t clear the machine or the loading dock, it bottlenecks productivity.

- Foundations that don’t meet spec

- Especially on older sites, floor-mounted jibs need slab thickness verification to avoid long-term fatigue or anchor failure.

- Retrofitting accessories to compensate for the wrong initial choice

Adding a powered trolley or remote control later often costs more than integrating it up front.

Instead of thinking in isolation, “What’s the SWL?” think in sequences:

- What’s being lifted?

- Who’s lifting it?

- How often?

- Where does it need to go?

Designing for workflow rather than just load data makes a measurable difference in efficiency and safety.

New vs Refurbished: Making the Right Call

There’s no universal answer when it comes to choosing between a new or refurbished jib crane. It’s not just about budget, it’s about environment, confidence, compliance, and future use. We’ve worked with plenty of teams who’ve made both choices for the right reasons.

If you're designing a new process line or fitting out a bay with tight tolerances, a new jib crane gives you full control - from boom length and mounting type to hoist travel and finishes. It also brings peace of mind when compliance is critical, especially in regulated settings like pharmaceuticals, food handling, or marine applications.

Refurbished jib cranes can be a smart choice when time and cost are under pressure. If the lifting requirements are standard, and the key dimensions of the Jib crane is not critical, a well-sourced refurbished crane can offer excellent value.

The key is understanding what you’re compromising, and what you’re not. A good refurbished unit will be fully LOLER compliant once installed and tested. But with anything that has been recycled parts now wear out quicker and need replacing sooner. Likewise, not all second-hand jib cranes are installation-ready; floor fixing interfaces, reach, or rotation limits often need close checking before committing.

In reality, many facilities run a mix: new jib cranes where performance, fit, or regulation demand it, refurbished ones for lighter-duty or secondary zones. The important thing is asking the right questions early. Because once the jib cranes are in, it needs to work without workarounds.

Planning a New Jib Crane Installation? Here’s What to Get Right

Installing a jib crane isn’t just a bolt-down job, or at least it shouldn’t be. Whether you’re adding a single jib crane to a workshop or integrating multiple stations into a new production line, the groundwork matters. Literally.

For floor-mounted systems, slab condition and foundation spec are often the first limiting factors. We've seen installations delayed or compromised because floor thickness or reinforcement wasn’t checked early. A standard bolt-down might look simple on paper, but if the concrete depth isn’t sufficient, you’re looking at core drilling, epoxy anchors, or a full foundation pad. Planning for this upfront avoids last-minute disruption, or worse, long-term structural issues.

Clamp around Column Mounted Jib Cranes require knowing what you're fixing to, how load is transferred, and whether the column/pillar/stanchion can take the dynamic forces involved. Just because there's steelwork in place doesn't mean it can take a crane.

Is there space for the jib arm to swing freely without hitting ductwork, lights, or racking? How much room above the jib is there? Is it going into a toolroom with low ceiling? Can materials be delivered to the install zone without disassembly? Can we get a forklift/access equipment into the area for installation?

Then there's certification. Every ULS installation is LOLER-compliant by default, but if you’re managing a site under CDM or integrating with wider mechanical works, we’ll liaise directly with your contractor or project lead to align safety, timelines, and commissioning.

A well-planned installation isn’t just about fitting the jib crane. It’s about ensuring it works, safely, efficiently, and without compromise, from day one.

When is it Time to Buy a New Jib Crane?

Jib cranes are built to last - but like any working asset, they don’t last forever. The trick is spotting the signs early, before a tired or misaligned setup starts affecting productivity or safety.

Sometimes, the signs are obvious. The hoist is no longer consistent. Bearings are starting to wear. The reach isn’t quite long enough, or the rotation arc now clashes with new racking or machinery. In other cases, the change is more subtle, a once-ideal jib crane is now being used in ways it was never designed for, whether that’s heavier loads, higher frequency, or more awkward lift paths.

Other times, it's the cost of patching that becomes the issue. You've already upgraded the hoist. The trolley's been replaced. You've added travel limiters, and remote control, but you're still working around the original crane's limitations. When you start adapting more than you're using, it's probably time to think again.

Then there’s growth. The process expands. The team scales. A layout changes. What was once a perfect fit becomes a bottleneck. In those cases, replacing the jib crane isn’t just a fix; it’s an opportunity to re-optimise the way your team moves, handles and lifts every day.

Buying a new jib crane doesn’t always mean scrapping the old one. Many clients repurpose older jib cranes into less demanding roles, or refurbish and relocate them elsewhere on site. But knowing when it’s time to stop working around the problem and start solving it is a great mark of operational maturity.

Key Considerations When Choosing a Jib Crane

Even if you’ve bought jib cranes before, no two installations are ever quite the same. Site layout, handling requirements, load characteristics - they all shift the spec. This isn’t about ticking boxes; it’s about choosing a configuration that performs reliably and safely for the long haul.

Working Load Limit (WLL)

The WLL isn't just about the heaviest load you'll lift, it's about factoring in regular use, potential shock loading, and the safety margin. Simply put it is the maximum load that can be lifted by the Jib Crane.

Height of Lift (HOL)

Always measure from the floor to the highest lift point, not just to the boom. Account for the hoist body and any required headroom clearance above the load.

Slew or Rotation Range

Standard ranges are 180°, 270° or full 360°, but the usable arc may be constrained by site layout. Think about what the jib crane could hit, not just what it should reach.

Arm Length (Reach)

Longer reach increases flexibility, but are there other structures or objects the arm might collide with? Maybe slew limits are required.

Mounting Type

Freestanding (floor-mounted), wall-mounted, or clamp-around column setups each have different structural and installation demands. Don’t assume your current layout can take the one you used last time - verify fixing points, access and clearances.

Hoist Selection

This can make or break productivity. Consider:

- Manual chain hoists for low-frequency or lighter loads

- Electric chain hoists for regular or heavier-duty use

- Push or geared travel trolleys for precise positioning

- Single or dual-speed operation depending on control needs

Accessories and Controls

Think beyond the lift. Remote controls, limiters, festoon systems, vacuum lifters, and block grippers all affect usability, safety, and efficiency, especially in multi-operator environments or when handling irregular loads.

Environment & Usage

Will the jib crane be exposed to weather, dust, or corrosive materials? Do you need stainless steel, galvanised finishes, or marine-grade components? The more accurate your use case, the better the outcome.

Advanced Jib Crane Considerations: Hoists, Attachments & Adaptability

Once a jib crane is installed, its true value is defined by how well it integrates into the task at hand. For experienced operators, performance isn't just about capacity; it's about control, adaptability, and the ease with which loads can be handled in context.

Hoist Control & Power Systems

- Check what voltage is available near the Jib location, 400volt/110volt

- Do you need powered travel along the jib arm

- Hoist control via wired pendant or radio remote control

Specialist Lifting Attachments

When your load isn’t simple, your lifting tools shouldn’t be either.

- Vacuum lifters, Bag Lifters, Plate Grabs and Lifting Magnets make short work of non-standard items - from sheet materials and boxed units to oddly shaped components.

Height of Lift

When determining your jib dimensions and the required height of lift (HOL), it’s important to factor in the space occupied by the jib arm itself. For example, a 500 kg overbraced jib with a 3m arm typically has an arm depth of around 80 cm. This reduces the overall height, in turn lowering the clearance to the underside of the arm.

For this reason, customers with limited headroom often choose an underbraced design, as it provides greater usable height beneath the arm.

Environmental Considerations

Working near water, in washdown zones, or in harsh conditions?

- Natural and synthetic rope options can provide critical corrosion resistance and longevity where traditional gear may degrade. Finishing, material choice, and ingress protection (IP) ratings all matter more in these settings than they do on the spec sheet.

Types of Jib Cranes - And Where They Really Work

Most people in the industry will know the standard labels: freestanding, wall-mounted, clamp-around. But understanding where each type performs best, and where it falls short, is what makes the difference in choosing the right configuration for your operation.

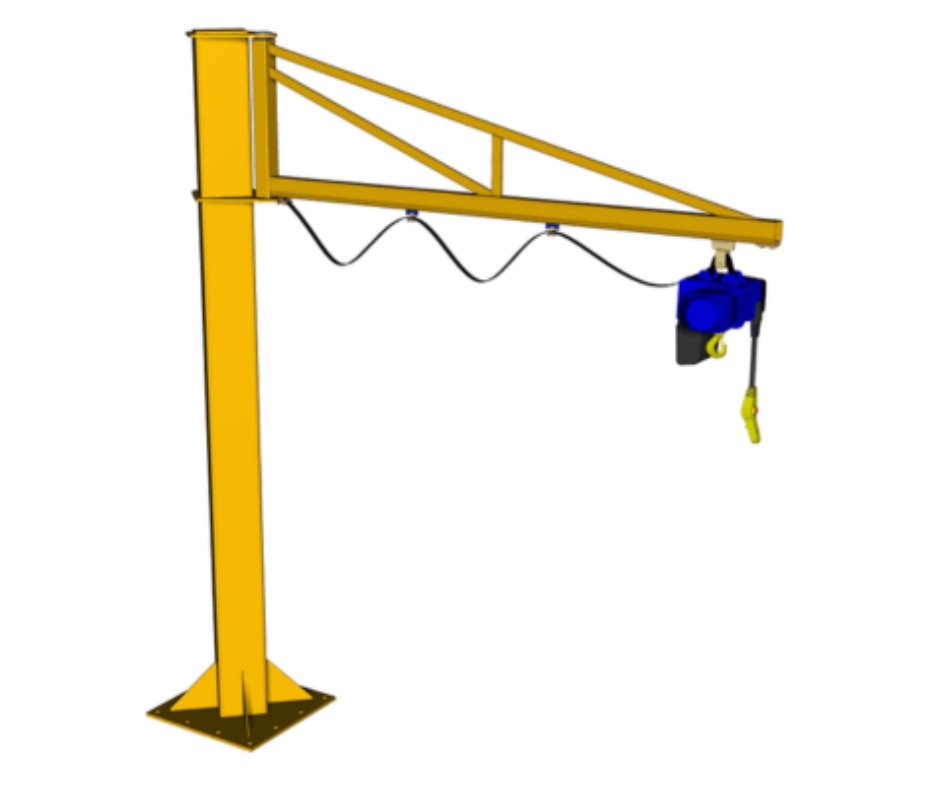

Freestanding Jib Cranes

The most flexible option, offering 270° rotation and can be positioned any where on a suitable floor. Ideal for maximum coverage in an open bay or when existing building structure can't support the load.

Considerations:

Please check floor strength – if in doubt, seek assistance from a structural engineer.

Wall-Mounted Jib Cranes

No need for a supporting column or stanchion to bolt to. Utilising existing walls frees up valuable shop floor space. Much cheaper to buy than floor floor-mounted Jib crane.

Considerations:

Please check the suitability of the wall; if in doubt, seek assistance from a structural engineer.

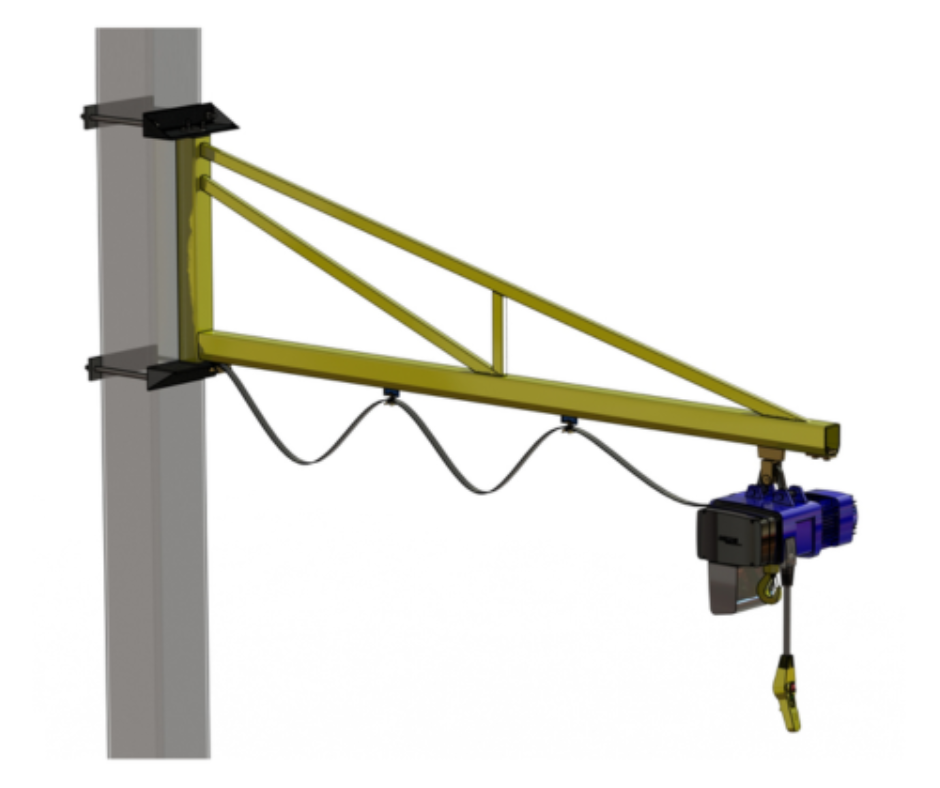

Column Mounted Jibs

Space-saving and cost-effective when a suitable structural column/stanchion already exists. Works well along production lines and on work stations.

Considerations:

Not suitable for all columns, please check the suitability of the wall; if in doubt, seek assistance from a structural engineer

Stainless Steel & Galvanised Options

For environments where hygiene or corrosion resistance is key, such as food production, chemical handling, or coastal/marine settings, material choice becomes critical.

Stainless steel cranes are non-reactive and easy to clean, while galvanised finishes offer robust protection for outdoor or semi-exposed applications.

Split-Column Designs

Where height or access is limited, split-column jibs offer an alternative way to maintain full lifting capacity in a compact format.

Useful in basements, mezzanines, or low-headroom areas that standard jibs can’t accommodate.

Davit Cranes

Often confused with jib cranes, davits offer a more portable, modular option for lifting lower weights in confined or mobile scenarios, think van-mounted setups, small workshops, or service vehicles.

They’re especially useful where quick setup and breakdown are needed, though they’re not designed for the same duty cycles as full jib systems.

For environments where hygiene or corrosion resistance is key, such as food production, chemical handling, or coastal/marine settings, stainless steel cranes are non-reactive and easy to clean, while galvanised finishes offer robust protection for outdoor or semi-exposed applications.

How We Work: From Jib Specification to Jib Crane Installation

Whether you're fitting out a new facility or replacing a jib crane that’s come to the end of its life, getting the right jib crane in place isn't just about product. It's about process. At ULS, we support that process from first enquiry to final sign-off, and beyond.

Step 1: Understanding Your Setup

Every successful crane starts with the right questions. We'll speak with you to understand your working environment, lifting requirements, floor or wall structure, and any known constraints - physical, logistical, or regulatory.

Some clients come to us with a full spec; others need help building one. Either is fine.

Key Questions We Ask

- What are you lifting and how heavy is it?

- How frequently will the crane be used?

- Floor-mounted or column-mounted?

- Are there any space constraints or obstacles?

- What are your specific workflow requirements?

- Do you require a hoist with your Jib Crane?

Step 2: Technical Review & Recommendations

Once we understand your brief, we’ll work with our engineers and project team to recommend the best-fit solution - whether that’s a new build, a refurbished jib crane, or a combination of systems across your site. We’ll flag any risks or dependencies early, including floor depth, ceiling clearance, or movement zones.

Step 3: Quotation with No Surprises

Your quotation will clearly outline the jib crane specification, any optional upgrades, delivery timelines, and installation scope (if required). We’re transparent about lead times and realistic about site conditions - and we’ll never quote until we’re confident the solution fits.

Step 4: Drawings & Approval

You'll receive dimensioned drawings for approval, showing:

- Layout and positioning

- Swing arc and coverage area

- Mounting interface details

- Access requirements

- Clearance specifications

- CAD files can be provided upon request.

This isn't just paperwork; it's where final adjustments happen. We'll liaise with your engineer, contractor or facilities team to make sure everyone's aligned before fabrication begins.

Step 5: Fabrication & Testing

Your Jib Crane is manufactured in the UK to your exact specification by our trusted manufacturing partners, with quality control at every stage, and will arrive fully certified.

You can expect:

- Quick delivery, usually within 10–14 working days

- Made to order, with no costs for excess steel or cutting

- Free and Easy to operate

- Low maintenance requirements

- Braking device to control slewing speed

- Lubrication-free acetyl bearings used on the majority of jib arms

- Base fabricated directly to pillar, so expensive foundation frames are not required

Hoists, controls, and attachments are matched to your application, and we're on hand throughout if any changes or questions arise. Testing and certification will be required after installation. If installed by ULS Lifting, this will be included as part of your package.

Step 6: Delivery & Installation

Schedule Coordination

We'll schedule work to suit your programme and minimise downtime, coordinating with your site team.

Professional Installation

Our engineers are experienced in working on live sites and follow strict safety protocols during installation.

Testing & Certification

As part of our installation service, we conduct all LOLER testing and certification as standard, ensuring your crane is fully compliant from day one.

Handover & Training

We provide comprehensive documentation and operator guidance to ensure safe, effective use.

If you're installing the crane in-house, we'll provide full documentation to assist your team.

Please note: in accordance with current LOLER (Lifting Operations and Lifting Equipment Regulations) requirements, the crane must be thoroughly examined and tested by a competent person after installation before being put into service. For complete peace of mind, our professional installation service includes this testing and certification as part of the package.

Step 7: Aftercare That’s Actually Helpful

Our support continues long after installation.

Your jib crane must be inspected and recertified annually under LOLER. Regular servicing not only keeps you compliant but also extends lifespan, reduces downtime, and avoids costly call-outs.

ULS Service & Maintenance Packages

From one-off annual services to bespoke maintenance plans, we cover:

- LOLER inspections & recertification

- Full mechanical/electrical checks & lubrication

- Preventive maintenance to minimise breakdowns

We schedule visits around your production and keep detailed records, so servicing is smooth, efficient, and hassle-free.

.png)

The Right Jib for Every Lift

No two workspaces are the same — so why settle for a one-size-fits-all jib crane? At Ultimate Lifting Solutions, we design, supply, and install lifting systems that fit your exact space, load, and workflow requirements.

Our range covers every style to help you lift smarter:

- Articulated Jib Arms – Perfect for working around obstacles or in tight spaces

- Goal Post Jibs – Large span coverage with open access

- A-Frame Mobile Gantry Cranes – Portable lifting for flexible operations

- Ceiling-Mounted Jibs – Save floor space while maximising reach

- Twin Arm Jibs – Extended coverage for multiple work zones

- Ultra-Low Headroom Jib Cranes – Ideal for restricted height environments

Why Choose ULS?

We focus on the solution that’s right for you, taking a consultative approach that asks the right questions and spots details others miss. Every jib crane is tailored to your site, team and workflow, supplied with engineer-ready drawings, clear communication, and fully briefed installation teams. Compliance is built in, all cranes are LOLER tested and certified, and our support continues long after installation, with full service records to make parts, modifications, or relocations quick and hassle-free. Choosing ULS means choosing safety, productivity, and long-term value.

Frequently Asked Questions: Jib Cranes

1. What’s the typical lead time for a new jib crane?

Lead times can vary depending on the specification and whether the jib crane is custom-built. For standard models, expect 2 to 4 weeks. For bespoke systems with custom boom lengths, hoists, or finishes, 6 to 10 weeks is more typical. Installation schedules may add to this depending on site readiness.

2. Can I install a jib crane myself, or should it be professionally installed?

While some experienced facilities teams may handle installation in-house, professional installation is strongly recommended. Factors like correct installation, accurate alignment, and LOLER compliance all impact long-term performance and safety. ULS offers full installation services to ensure correct setup and certification.

3. What kind of foundation or floor spec is needed for a freestanding jib crane?

We always advise customers to seek professional assistance from a qualified structural engineer.

4. How often should a jib crane be inspected under LOLER?

LOLER regulations require lifting equipment to be inspected at least every 12 months. If the jib crane is used constantly all day, every day, we would discuss that inspections must occur every 6 months.

5. Can I retrofit powered rotation or a different hoist later on?

Yes, in many cases. Powered rotation systems, upgraded trolleys, or electric chain hoists can be added later, but it depends on the original jib crane’s design and mounting. It’s best to specify future requirements upfront, but we can advise on retrofitting existing systems.

6. What are the benefits of dual-speed hoists vs single-speed?

Dual-speed hoists offer greater control, especially during precise lifting or when handling delicate loads. They allow faster travel for positioning, then slower movement for accurate placement. In high-use or multi-operator environments, they improve both efficiency and safety.

7. Can a jib crane be relocated if we move or reconfigure our workspace?

Yes - many jib cranes can be dismantled and reinstalled elsewhere, though freestanding jib cranes may require a new foundation. It’s important to reassess floor conditions, loading requirements, and layout constraints before relocation. ULS offers relocation support and re-certification.

8. What’s the difference between a jib crane and a davit or swing arm?

Jib cranes are typically fixed, heavy-duty lifting systems with a rotating boom and higher load capacity. Davits are more portable, modular, and suited to lighter-duty applications (e.g. maintenance vehicles or small-scale lifts). Swing arms often refer to smaller, non-motorised variants of jib cranes.

9. Do refurbished jib cranes still need to be LOLER tested?

Yes. Any refurbished or second-hand jib crane must be thoroughly inspected and tested before use. ULS provides LOLER-compliant certification as standard with all refurbished systems, including proof of inspection and safe working load verification.

10. What’s the typical lifespan of a well-maintained jib crane?

A quality jib crane can last 15–20 years or more with regular maintenance. Key components like bearings, hoists and trolleys may need periodic replacement. Proper installation, usage within spec and scheduled inspections all extend service life.

11. How do I choose the right hoist for a jib crane?

It depends on your load type, lift frequency, environment and control preference. Manual chain hoists suit low-volume lifting, while electric chain hoists are ideal for repetitive or heavier use. Push or geared travel trolleys allow precise positioning. For best results, match hoist type to workflow, not just weight.

12. Do I need planning permission to install a jib crane?

In most industrial or commercial settings, planning permission isn’t required. However, jib cranes installed externally or in listed buildings may be subject to local authority rules. It’s always worth checking with your site manager or facilities consultant. ULS can provide supporting documentation if needed.

13. What’s the difference between a wall-mounted and floor-mounted jib crane?

Wall-mounted jib cranes save floor space and are ideal when structural support is available. They typically offer 180–200° rotation. Floor-mounted (freestanding) jib cranes offer full 360° coverage and greater flexibility but require a suitable foundation. The choice depends on available space, structure, and desired reach.

14. Is a jib crane the best choice for my application, or should I consider an overhead system?

It depends on the lifting zone, coverage area, and workflow. Jib cranes are ideal for localised, repetitive lifts, especially at workstations or fixed bays. For larger or multi-bay coverage, overhead gantry or bridge cranes may be more suitable. ULS can advise based on your specific layout and usage patterns.

15. Can I use a jib crane outdoors or in a marine environment?

Yes, but the system needs to be specified accordingly. Galvanised finishes, stainless steel components, sealed bearings and weatherproof enclosures are often required. ULS can provide outdoor-rated or marine-ready jib cranes built to withstand harsh conditions.

16. What should I check before buying a second-hand jib crane?

Check the jib crane’s inspection history, visible wear on hoist and bearings, compatibility with your layout, and whether the base or mounting interface matches your structure. Ensure it has a valid LOLER certificate or can be re-certified before use.

17. What safety features should be included on a modern jib crane?

Standard features often include load limiters, rotation stops, hoist limit switches, and overload protection. Additional options like remote control systems and anti-drop devices are available. Safety requirements vary by environment - our team can help you specify what's needed for full compliance and user safety.

.png)