Cranes

Cranes

Ultimate Lifting Solutions Ltd is a UK-based leading supplier of quality manufactured wall mounted, column mounted, free standing jib cranes, and under-braced jib cranes with and without electric hoists or manual hoists. We pride ourselves on not only designing and supplying off-the-shelf lightweight crane systems and bespoke under-braced jib cranes for many industrial applications, but can also aid from the initial design of the crane for more bespoke applications or needs. Once plans have been approved, Ultimate Lifting Solutions will fully manage the crane manufacture and can deliver your lifting crane anywhere in the UK. As well as being a leading provider of quality cranes, Ultimate Lifting Solutions can also support the installation of your crane system or help you and your business with the complete, full package of design, supply, delivery, and installation of lifting cranes.

We also supply crane accessories and scaffold runway systems to complement our comprehensive range of cranes, jib cranes, free-standing jib cranes, and jib arms. Simply scroll down to explore the range of ULS cranes for sale.

Feel free to call us on 01384 986 026 to discuss your crane requirements; our technical sales team is here and ready to discuss your requirements.

360 Degree Column Jib Crane 250Kg Capacity

360 Degree Column Jib Crane 250Kg Capacity

RJC

360 Degree Column Jib Crane offers total flexibility within the workplace. The crane arm has full rotation around the main upright column, providing a complete circular lifting aid of up to 6m. Overall column height can be manufactured up to 6m Tall

£1,698.98 ex VAT

£2,038.78 inc VAT

Magnetek Flex Base Replacement Transmitter

Magnetek Flex Base Replacement Transmitter

FLEX-BASE-TX

Magnetek Flex Base Replacement Transmitters are available from ULS Lifting from stock on fast delivery to anywhere in the UK. Call today to replace your broken Flex Base Controller, available in four different sizes Flex 4 Base, Flex 6 Base, Flex 8 Base, and Flex 12 Base.

£398.98 ex VAT

£478.78 inc VAT

Magnetek Flex Wave Replacement Transmitter

Magnetek Flex Wave Replacement Transmitter

FLEX-WAVE-TX

Magnetek Flex Wave Replacement Transmitters are available from ULS Lifting from stock on fast delivery to anywhere in the UK. The Flex EX2 spare/replacement handset is available in 4-button, 6-button, 8 button, and 12 button models

£474.98 ex VAT

£569.98 inc VAT

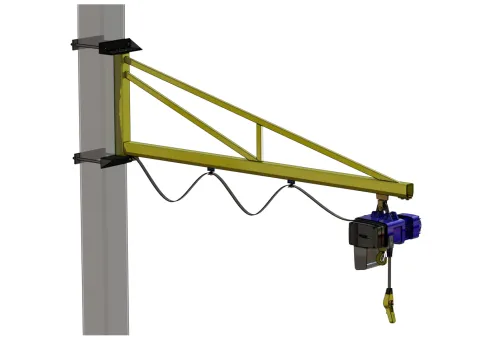

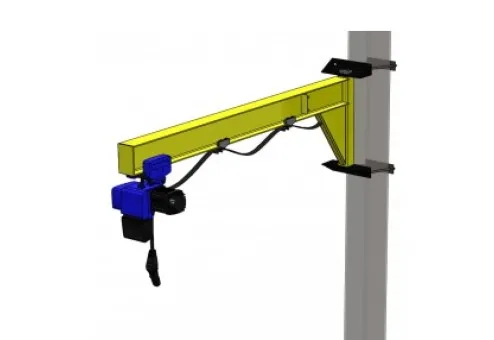

80Kgs SWL Column Jib Crane c/w Electric Hoist

80Kgs SWL Column Jib Crane c/w Electric Hoist

CMJC

80Kgs SWL Column Jib Crane c/w Electric Hoist is manufactured in the UK. These 80Kgs Column Mounted or I-BEAM Mounted Jib cranes are supplied complete with a quality 400v Electric Chain Hoist, this saves you time in selecting which hoist and trolley to order with your Jib arm. Just confirm the working height and Jib Arm length.

£509.98 ex VAT

£611.98 inc VAT

80Kgs SWL Column Jib Crane c/w Manual Chain Hoist

80Kgs SWL Column Jib Crane c/w Manual Chain Hoist

CMJC

80Kgs SWL Column Jib Crane c/w Manual Chain Hoist is manufactured in the UK. These I-Beam or Column Mounted Jib Arms are supplied complete with a quality manual chain hoist, this will save you time in selecting which hoist and trolley to order. These column Jib cranes are ideal if you are looking for a crane suspended securely from an existing column, pillar, or stanchion within your building.

£509.98 ex VAT

£611.98 inc VAT

80Kgs SWL Column Mounted Jib Crane Galvanised Finish for Outdoor Usage

80Kgs SWL Column Mounted Jib Crane Galvanised Finish for Outdoor Usage

CMJC-GALV

£1,048.88 ex VAT

£1,258.66 inc VAT

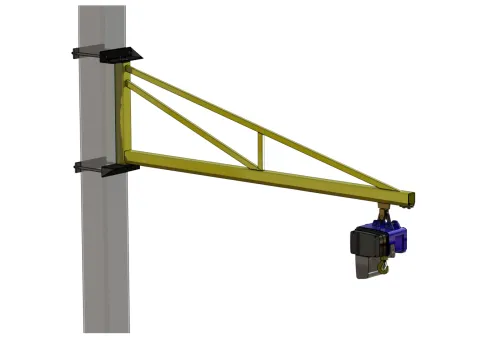

80Kgs SWL Column Mounted Jib Cranes - Over Braced

80Kgs SWL Column Mounted Jib Cranes - Over Braced

CMJC

80Kgs SWL Column Mounted Jib Cranes - Over Braced versions that are manufactured in the UK. Also known as a clamp around the Jib crane as the supporting brackets can be attached to any suitable building column/stanchion or pillar.

£498.98 ex VAT

£598.78 inc VAT

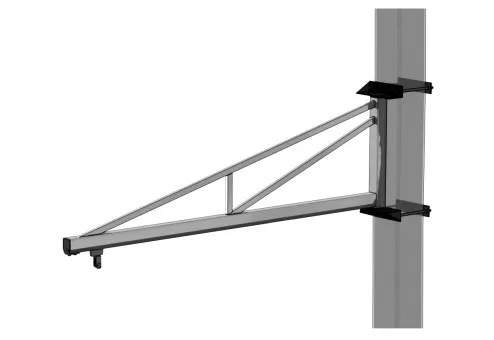

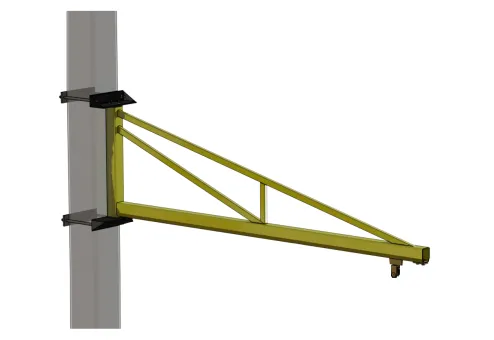

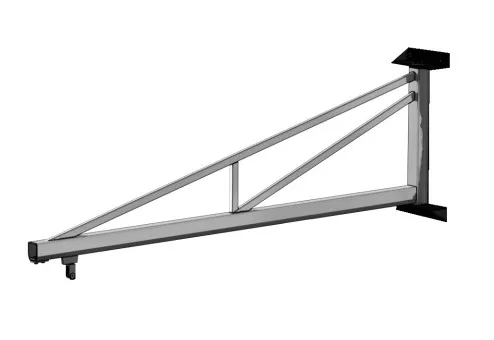

80Kgs SWL Column Mounted Jib Cranes - Under-Braced

80Kgs SWL Column Mounted Jib Cranes - Under-Braced

UBCMJC

80Kgs SWL Column Mounted Jib Cranes - Under-Braced. Manufactured in the UK. Designed for low-height situations or use with an electric hoist and powered trolley. Jib Arm can be supplied to any length between 2m-6m and slew through 180° giving a very wide working area.

£848.98 ex VAT

£1,018.78 inc VAT

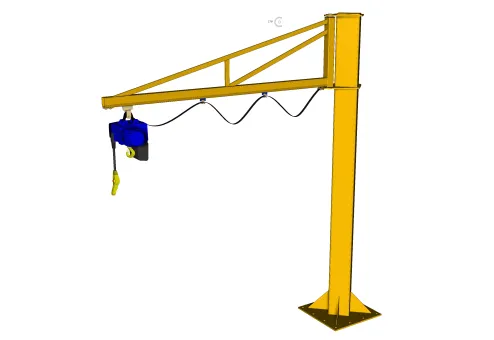

80Kgs SWL Free Standing Jib Crane - Over Braced

80Kgs SWL Free Standing Jib Crane - Over Braced

FJC

£998.98 ex VAT

£1,198.78 inc VAT

-494x340.webp) 80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced

80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced

FJC

80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced version manufactured to order. various options available on both arm length and height of Jib Crane. All our swing Jib Cranes are manufactured to order. These 80Kgs rated Freestanding Jib cranes are supplied with a quality 400-volt Electric Chain hoist (110-volt and 240-volt options available on request).

£998.98 ex VAT

£1,198.78 inc VAT

-494x340.webp) 80Kgs SWL Free Standing Jib Crane c/w Manual Chain Hoist

80Kgs SWL Free Standing Jib Crane c/w Manual Chain Hoist

FJC

80Kgs SWL Free Standing Jib Crane c/w Manual Chain Hoist. This lightweight Profiled version of the ULS Lifting Free Standing Jib crane range comes complete with a quality manual chain hoist, that will simply hook onto the Jib Crane Manual Trolley already fitted to the swinging Jib Arm.

£998.98 ex VAT

£1,198.78 inc VAT

80Kgs SWL Wall Mounted Jib Crane Galvanised Finish for Outdoor Usage

80Kgs SWL Wall Mounted Jib Crane Galvanised Finish for Outdoor Usage

WMJC-GALV

80Kgs SWL Wall Mounted Jib Crane Galvanised Finish for Outdoor Usage can also be used indoors in areas that will be subjected to any type of moisture. the Swing Arm can be made to any length from 2m to 6m. All Galvanised Wall or Face Fixed Jib Cranes are manufactured in the UK.

£988.98 ex VAT

£1,186.78 inc VAT

Lifting Crane Systems by Ultimate Lifting Solutions Ltd

Choosing a crane system may seem complicated, but talking to Ultimate Lifting Solutions today on sales@ulslifting.com or 01384 986 026 about your lifting needs is the first step in finding the correct crane for your needs. Whether you're searching for a simple a-frame gantry, a lightweight braced jib crane, or a wall or column-mounted jib arm, our team are here to help you source what you need for your next project.

We can also offer bespoke crane systems, including low-height swing jibs and I-beam style freestanding jib cranes to meet your requirements – we are also capable of supplying cranes for tool rooms and machine shops, as well as offering crane solutions for rooms with height restrictions.

All of ULS's cranes are manufactured from quality materials and supplied with the latest certifications and warranties.

What is a lifting crane?

The primary function of a crane is to lift and move heavy objects or manufactured components from one point to another. Additionally, crane systems transport materials along a boom or jib arm, allowing them to access most corners and spaces within a factory. By integrating a crane into your building, you can maximize the use of your shop floor whilst vastly improving your productivity.

How do cranes work?

A crane is generally equipped with a hoist. This hoist can be a wire rope hoist, an electric hoist, a manual hoist, or a tool balancer. The hoist fitted to the crane will lift an object off a machine, such as a lathe or a finished component from a bench, or if the crane is in a loading bay, it can aid in loading or unloading vehicles. Once the load has been lifted, the crane can move sideways and up or down across a factory floor. These warehouse cranes can manoeuvre materials by raising them above any machines or other items around a factory, moved sideways along its boom arm, and then placed down in most positions in a factory, workplace or outside the factory yard.

Where did cranes come from?

Cranes are believed to date back to 3000BC and were known as the Shadouf, a straightforward design with a lever mechanism to lift water. The ancient Greeks were first thought to use a crane for lifting, and it is believed the heyday of the crane in ancient times came during the Roman Empire. The first modern cranes were installed at busy harbors for loading all types of cargo, and while the design has changed a lot since the first cranes were created, the principles have always stayed the same.

What Types Of Cranes Are There?

Gantry Cranes come in two main designs; both are goalpost designs with a hoist fitted at the top. The difference is that a gantry crane can be equipped with a single beam known as a monorail across two goalposts. These are suitable when the crane's span is relatively short. If the span required is more extensive, such as stretching the entire width of a factory floor, then a two-beam design is better, otherwise known as a twin girder gantry crane. The twin girder crane can stretch and fall across a factory and run the entire length of a factory and is fitted usually with a wire rope hoist.

The Jib Crane or Swing Jib is a type of crane with a hoist fitted to a horizontal beam commonly called a jib arm or boom arm. The hoist can move along the jib arm, giving flexibility with a long reach. The jib arm can be fixed, swivelling or even articulated. Swing jibs are commonly used inside factories and outside at harbors, whilst jib cranes are used on construction sites. If fitted to a vertical post or column, the jib crane can be floor mounted, commonly known as a freestanding floor crane, and is usually fixed to a concrete floor. Jib cranes are very flexible and can be fitted to a factory wall, and swing jibs can be fitted to a vertical I-beam or to factory steelwork at any height required.

Purchasing a crane with ULS

ULS Cranes For Sale

Here at ULS, we proudly supply overhead crane systems, under-braced swing jibs, heavy-duty jib cranes, counterbalanced floor cranes, bridge cranes, lightweight profile track and trolley jib cranes, swing jibs, gantry cranes, monorail cranes, special purpose cranes, a-frame cranes and portable a-frame cranes. If we don't have the type of product you'd like on our website, please get in touch - ULS have access to thousands of products that we don't list online, and a member of our team would be happy to help source the product cranes and hoists you're searching for!

In addition to the Ultimate Lifting Solutions range of warehouse cranes, jib cranes, freestanding jib cranes and wall-mounted jib arms, we also supply an extensive range of crane accessories and our scaffold runway systems. Our crane accessories include cable festoon systems which help get power cables along a track to feed overhead hoists and other machinery that needs a power supply or control supply. We also supply remote radio systems and radio remote spare parts such as replacement radio remote batteries for the Arc Flex range of radio remote systems and replacement directional legends and radio remote replacement stickers - one of our most popular ranges of radio remote systems is the Arc Flex radio remote system, these can be easily retro-fitted any most electric chain hoists or overhead cranes.

Our Scaffold Runway Systems clamp directly to existing scaffold structures and, once fitted with a suitable hoist, will help lift and transport building materials to 1600 kg (1.6 tonnes) up the scaffold system to your desired level. The track can be bought in 3m sections and comes complete with an integral trolley to help you transport your building materials or site waste around the scaffold system to the desired position. We can even supply bends if required. The great advantage of the scaffold runway system for cranes and hoists is that we deliver our systems in modular form to keep the weight down for easy and fast assembly or dismantling and re-positioning to a new level or dismantling for easy storage.

If you are in the market to buy a crane and have any questions, or require a quotation for one of our products before you buy a crane, contact Ultimate Lifting Solutions today to discuss your requirements: tel 01384 986 026 or email sales@ulslifting.com.