80Kgs SWL Free Standing Jib Crane - Over Braced

Key notes for ordering:

Dispatched as a kit with instructions, decide on extras like isolator for electrics, festoon system for elec hoist. Contact us for installation prices. Suppled with certification

Estimated lead time:Manufactured in UK to Order Approx. 3 - 4 Weeks Delivery

Please call us if you need this item sooner

& COLLECT

delivery

DELIVERY

(Call us)

Seen this product cheaper elsewhere?

We will always try to offer this product at the best price. We will do our best to not just match it but to beat it.

Price match

promise

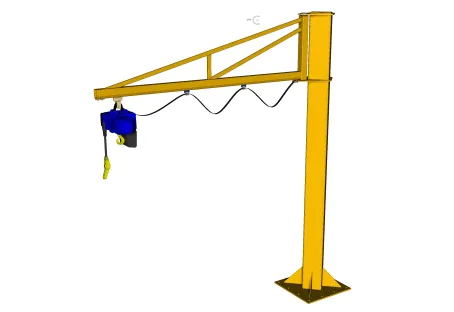

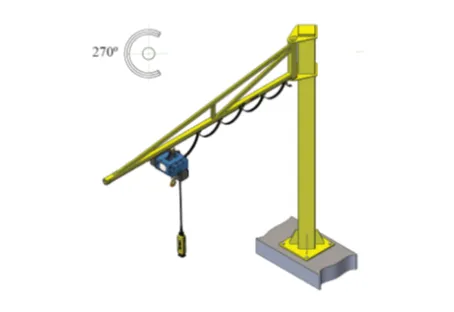

80Kgs SWL Free Standing Jib Crane - Over Braced

Capacity

80Kgs

Description

80Kgs SWL Free Standing Jib Crane - Over Braced supplied fully tested and certified. Lightweight in design, Over-Braced Freestanding Jib cranes can be manufactured to suit your requirements to create an affordable yet versatile solution for moving objects on and off machinery or around the factory floor and into hard-to-reach areas. Supplied in a simple two-part kit form.

£998.98 ex VAT

£1,198.78 inc VAT

1 - Adjustable Slew Limits

2 - Slewing Lock

3 - Installation

Related products

-494x340.webp) Festoon System for Overhead Cranes & Hoists

Festoon System for Overhead Cranes & Hoists

FEST SS

C Rail Style Festoon System (Full Kit) including flat form power cable, cable trolleys & track. These simple-to-install lightweight kits provide a safe and economical means of supplying power to overhead hoists, overhead cranes, and most other types of moving machinery that travels along a fixed track. Once fitted eliminates dangerous dangling down cables and looks like a professional install or refit

£124.98 ex VAT

£149.98 inc VAT

-494x340.webp) 80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced

80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced

FJC

80Kgs SWL Free Standing Jib Crane c/w Electric Hoist - Over Braced version manufactured to order. various options available on both arm length and height of Jib Crane. All our swing Jib Cranes are manufactured to order. These 80Kgs rated Freestanding Jib cranes are supplied with a quality 400-volt Electric Chain hoist (110-volt and 240-volt options available on request).

£998.98 ex VAT

£989.99 ex VAT

£1,187.99 inc VAT

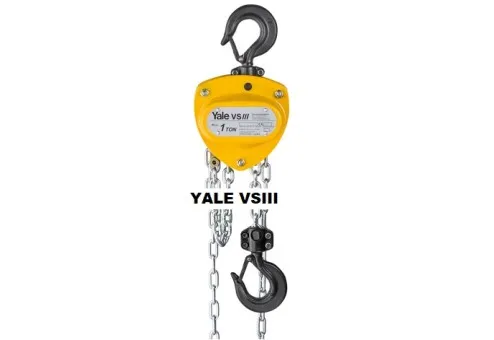

VSIII Yale Manual Hand Chain Hoist

VSIII Yale Manual Hand Chain Hoist

VSIII

£113.98 ex VAT

£136.78 inc VAT

-494x340.webp) Stahl ST Electric Chain Hoist - 400 volt output

Stahl ST Electric Chain Hoist - 400 volt output

ST

The Stahl ST Electric Chain Hoist is a powerful yet energy-efficient solution, demanding minimal maintenance while delivering consistent, high-performance lifting.

£1,029.98 ex VAT

£1,235.98 inc VAT

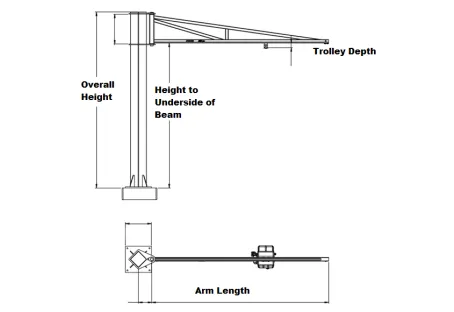

| Model | SWL | Working Height to the underside of the beam | Overall height of Jib | Trolley depth | Arm Length (Radius of reach) | Total Weight |

| FJC80R3 | 80Kgs | 2,500mm (2.5m) | 3,000mm (3m) | 65mm | 3,000mm (3m) | 200Kgs |

| FJC80R4 | 80Kgs | 2,400mm (2.4m) | 3,000mm (3m) | 65mm | 4,000mm (4m) | 220Kgs |

| FJC80R5 | 80Kgs | 2,100mm (2.1m) | 3,000mm (3m) | 65mm | 5000mm (5m) | 230Kgs |

| FJC80R6 | 80Kgs | 2,900mm (2.9m) | 3,000mm (3m) | 77mm | 6,000mm (6m) | 350Kgs |

More products from category:

Lifting Equipment

110 Volt Scaffold Hoist 200kg Capacity

110 Volt Scaffold Hoist 200kg Capacity

DM200i

The 110-volt Scaffold Hoist has a 200 kg capacity and comes with a swivel bracket for direct attachment to scaffold tubes. It features a lifting height of 25 meters and a lifting speed of 25 meters per minute. This high-quality hoist is designed for professional builders and heavy-duty lifting. The DM200I is quickly becoming a customer favorite and one of our top-selling products.

£794.98 ex VAT

£953.98 inc VAT

360 Degree Column Jib Crane 250Kg Capacity

360 Degree Column Jib Crane 250Kg Capacity

RJC

360 Degree Column Jib Crane offers total flexibility within the workplace. The crane arm has full rotation around the main upright column, providing a complete circular lifting aid of up to 6m. Overall column height can be manufactured up to 6m Tall

£1,698.98 ex VAT

£2,038.78 inc VAT

BlueLink Bluetooth Digital Dynamometer

BlueLink Bluetooth Digital Dynamometer

BLD6T5

£1,069.98 ex VAT

£1,283.98 inc VAT

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar

The CM BatteryStar is the brand new Battery Powered Chain hoist that has been built with industry-leading technology from Columbus McKinnon and Milwaukee Tool. Designed for portability and easy installation, the BatteryStar can have you lifting in minutes. Supplied without Battery/Charger as standard

£2,498.98 ex VAT

£2,998.78 inc VAT

SUBSCRIBE FOR THE LATEST NEWS & SPECIAL OFFERS

Sign up here to get the latest news, updates and special offers delivered to your inbox.

Add to cart

Add to cart Add to quote

Add to quote