SXD / SXF Wire Rope Hoist | STAHL Crane Systems

-88x60.webp)

-88x60.webp)

-88x60.webp)

-88x60.webp)

Seen this product cheaper elsewhere?

We will always try to offer this product at the best price. We will do our best to not just match it but to beat it.

Price match

promise

SXD / SXF Wire Rope Hoist | STAHL Crane Systems

Description

Compact STAHL SXD and SXF Wire Rope Hoists (2–10 t) with dual-speed or frequency control, Dynamic Lift System (DLS) and SMC 4 safety monitoring. LOLER and UKCA compliant.

P.O.A

Related products

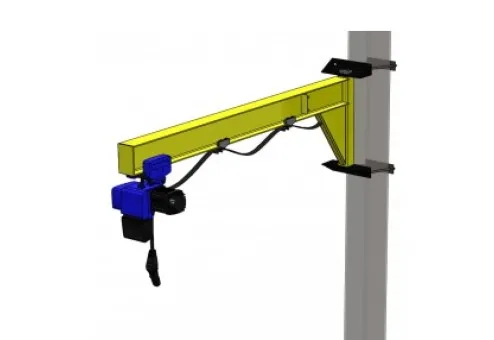

125Kgs SWL Column Mounted Jib Cranes - Under-Braced

125Kgs SWL Column Mounted Jib Cranes - Under-Braced

UBCMJC

125Kgs SWL Column Mounted Jib Cranes - Under-Braced version, manufactured in UK and can be made to bespoke dimensions. Under-braced Jib Cranes are Ideal for use in a factory that needs a Jib crane to be bolted or welded to structural steelwork, pillars, or stanchions.

£898.98 ex VAT

£1,078.78 inc VAT

The SXD / SXF Wire Rope Hoist range from STAHL Crane Systems delivers reliable lifting performance for all industrial and manufacturing environments.

Technical Features

Compact, weight-optimised design

High-efficiency gearbox

Optimised drive shaft

Plug-and-Play electrics

Monorail trolley (KE-X)

Dynamic Lift System (DLS)

Magnetek IMPULSE·G+ Mini converter

SMC 4 Multicontroller

Temperature-managed motor & brake

Rope and rope-guide system

Key Features

Load capacity: 2 t – 10 t with 4 / 1 reeving

Compact build: reduced headroom, improved approach dimensions

Plug-and-Play installation: quick electrical connection, no specialist tools

Dynamic Lift System (DLS): automatically adjusts lifting speed to load (up to 300 %)

Ultra-smooth motion: Magnetek IMPULSE·G+ Mini converter with regenerative braking

Precision control: SMC 4 Multicontroller monitors load, speed and temperature in real-time

Overload protection: continuous electronic monitoring at rope anchor point

Finger-protection system: guards operators during hook-block operation

Maintenance-free gearbox: vented and sealed for lifetime lubrication

Temperature and condition monitoring: prevents overheating and extends service life

Radio or pendant control options: push-button or master-switch ergonomics

CraneKit ready: integrate easily into single- or double-girder cranes

Maintenance and Servicing

The KE-X monorail trolley allows fitting to existing monorail systems or single-girder cranes, with flange adjustment from 90 – 500 mm. The dual-drive shaft design distributes load evenly across the trolley wheels for smooth travel and minimal wear. Optional travel-limit switches and towing arms improve positioning accuracy and operator safety. ULS engineers can install, commission and test your Stahl Wire Rope Hoist in line with LOLER and PUWER requirements, supplying full certification on completion.

Safety Features

Every SXD / SXF hoist is built around active protection and intelligent monitoring to safeguard both operator and equipment.

Integrated electronic overload protection

Continuous load measurement at the rope anchor point prevents overloading and automatically limits the hoist to its rated capacity.

Emergency upper & lower limit switches

Dual gear limit system protects against over-travel in both directions.

Condition monitoring & anti-jogging logic

Motor management suppresses excessive inching movements, reducing thermal and mechanical stress on the drivetrain.

Redundant safety brake system

Frequency-controlled SXF variant uses continuous speed and load monitoring; brakes act only as holding or emergency brakes to minimise wear. Fully compliant with EN 14492-2, EN 15011, and EN 13001-2.

Safe torque shut-off (STO)

Hardware-based safety circuit instantly removes motor and brake power if an emergency stop or fault signal occurs.

Finger-protection system

Newly developed guard elements prevent hands from entering the hook-block or running-rope area while maintaining rope-angle flexibility.

Temperature and phase monitoring

Continuous detection of motor overheating, short-circuit, or phase loss. Faults are logged for diagnostics.

Load-dependent speed control (DLS)

Protects structural and electrical components by reducing speed automatically as load approaches full capacity.

Lifetime-lubricated gearbox & vent system

Prevents pressure build-up, leaks, and contamination—reducing maintenance-related risk.

Compliance & standards

Conforms to EN 61800-5-2, EN 61508, SIL 2, DIN EN ISO 13849-1 PL c, LOLER, and UKCA marking requirements.

.

*Weight note:

SXD 4 / SXF 4 body with drum length L2H ≈ 310 – 340 kg, L3H ≈ 340 – 370 kg.

SXD 5 / SXF 5 body with drum length L2H ≈ 556 – 595 kg, L3H ≈ 626 – 665 kg.

These values are published in the brochure and vary with drum length and whether it’s SXD or SXF.

Full dimensional drawings and trolley options available on request.

What’s the difference between SXD and SXF?

SXD is a dual-speed hoist for straightforward lifting. SXF adds a frequency converter and DLS for variable-speed control, better precision and faster part-load operation.

Can the hoist be fitted to an existing monorail?

Yes. The KE-X trolley can be mounted directly beneath the beam and adjusted on site without special tools.

Is the gearbox maintenance-free?

Yes. The sealed gearbox uses lifetime lubrication with vented pressure equalisation-no oil changes required.

Does it include overload protection?

Every unit has electronic load monitoring calibrated to its rated capacity, protecting both the hoist and the operator.

What control options are available?

Standard push-button pendant or optional Magnetek radio remote with master switch functionality.

More products from category:

Hoists

110 Volt Scaffold Hoist 200kg Capacity

110 Volt Scaffold Hoist 200kg Capacity

DM200i

The 110-volt Scaffold Hoist has a 200 kg capacity and comes with a swivel bracket for direct attachment to scaffold tubes. It features a lifting height of 25 meters and a lifting speed of 25 meters per minute. This high-quality hoist is designed for professional builders and heavy-duty lifting. The DM200I is quickly becoming a customer favorite and one of our top-selling products.

£834.98 ex VAT

£1,001.98 inc VAT

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar

The CM BatteryStar 1000Kgs Battery Powered Chain Hoist is a revolutionary battery hoist built with industry-leading technology from Columbus McKinnon and Milwaukee Tool. Designed for maximum portability and rapid installation, this powerful battery-powered hoist gets you lifting in minutes. Supplied without Battery/Charger as standard.

£2,498.98 ex VAT

£2,333.33 ex VAT

£2,800.00 inc VAT

ET200 IMER Scaffold Hoist Extension Pole

ET200 IMER Scaffold Hoist Extension Pole

1199170

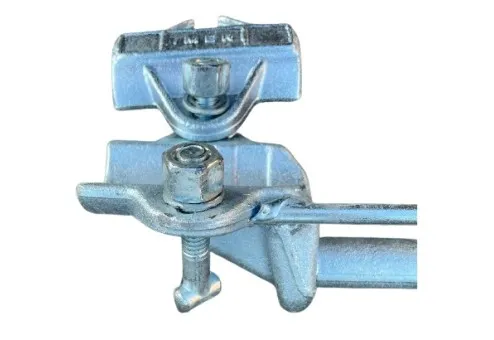

ET200 IMER Scaffold Hoist Extension Pole is an official IMER product and is supplied with 3 scaffold clamps for quick and easy attachment to standard scaffold tubing. Once the Imer Extension Pole is fitted the ET200N Imer Scaffold Hoist can be attached

£209.99 ex VAT

£251.99 inc VAT

GT Viper Chain Block

GT Viper Chain Block

HSZ-L - VCB

The GT Viper Chain Block range offers heavy-duty, industrial-quality chain hoists from 500 Kgs to 30 tonnes, including a highly sought-after 1 ton chain block. Features include a matt black finish and secure HD catches on both hooks. Buy online today!

£69.98 ex VAT

£83.98 inc VAT

SUBSCRIBE FOR THE LATEST NEWS & SPECIAL OFFERS

Sign up here to get the latest news, updates and special offers delivered to your inbox.

-454x312.webp)

-454x312.webp)

-454x312.webp)

-454x312.webp)

Add to quote

Add to quote