Lifting Eye Bolts & Eye Nuts (Swivel & Non-Swivel)

Lifting Eye Bolts & Eye Nuts (Swivel & Non-Swivel)

Welcome to the ULS Lifting storefront, your specialist source for a comprehensive selection of certified Lifting Eye Bolts and Eye Nuts. We understand that secure, reliable lifting operations begin with high-quality, load-rated rigging hardware. Our extensive inventory covers every application, from heavy-duty collared eye bolts and non-swivel eye nuts for stable vertical lifts to advanced swivel lifting points and swivel eye nuts designed for safe angular loading.

We cater to diverse industrial needs by stocking products with metric threads, imperial threads, and extra-long shanks to ensure compatibility with your specific machinery or structure. Partnering with all leading manufacturers, ULS provides only CE marked, fully compliant lifting accessories. Every order is dispatched with the necessary paperwork and EC Declarations, guaranteeing that your load-rated equipment is ready for immediate use upon delivery.

DIN582 Eyenut Zinc Plated

DIN582 Eyenut Zinc Plated

DINENZP

£0.89 ex VAT

£1.07 inc VAT

Grade 8 Eyebolt - High capacity

Grade 8 Eyebolt - High capacity

XN054

£2.45 ex VAT

£2.94 inc VAT

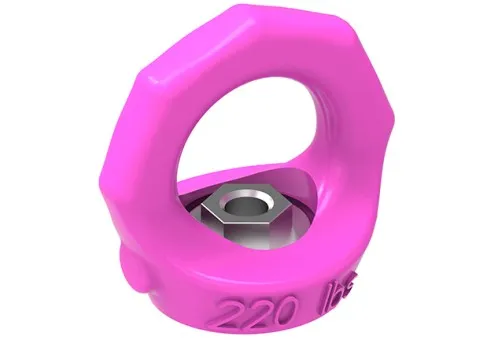

Grade 8 Eyenut - High capacity

Grade 8 Eyenut - High capacity

XN055

£2.08 ex VAT

£2.50 inc VAT

Grade 8 Pivoting Eyebolt with load ring

Grade 8 Pivoting Eyebolt with load ring

XN173

£18.45 ex VAT

£22.14 inc VAT

Grade 8 Pivoting Eyebolt with load ring - Extra Long Thread

Grade 8 Pivoting Eyebolt with load ring - Extra Long Thread

XN173 EL

£23.95 ex VAT

£28.74 inc VAT

Grade 8 Swivel Eyebolt with Ring

Grade 8 Swivel Eyebolt with Ring

XN303

£12.55 ex VAT

£15.06 inc VAT

Grade 8 Swivel Eyebolt with Ring - Extra Long Thread

Grade 8 Swivel Eyebolt with Ring - Extra Long Thread

XN303

£15.65 ex VAT

£18.78 inc VAT

RUD VLBG-PLUS Load Ring, Metric c/w Variable Bolt

RUD VLBG-PLUS Load Ring, Metric c/w Variable Bolt

VLBG-PLUS VAR

£91.97 ex VAT

£110.36 inc VAT

RUD VLBG-PLUS Load Ring, Metric thread

RUD VLBG-PLUS Load Ring, Metric thread

VLBG-PLUS

£76.97 ex VAT

£92.36 inc VAT

RUD VRM Starpoint Eyenut Metric thread

RUD VRM Starpoint Eyenut Metric thread

VRM Starpoint

£56.05 ex VAT

£67.26 inc VAT

RUD VRS-F Starpoint Eye Bolt, Metric Thread

RUD VRS-F Starpoint Eye Bolt, Metric Thread

VRS-F Starpoint

£44.90 ex VAT

£53.88 inc VAT

RUD VWBG Load Ring, Metric thread

RUD VWBG Load Ring, Metric thread

VWBG

£409.85 ex VAT

£491.82 inc VAT

Selecting the Right Lifting Hardware: Safety, Standards, and Specifications

Choosing the correct lifting eye bolt or eye nut is paramount for operational safety and regulatory compliance. At ULS, we provide comprehensive product specifications to guide your selection, ensuring you receive a component rated for your precise Working Load Limit (WLL) requirements.

Understanding Swivel vs. Fixed Lifting Points: It is critical to understand the distinction between fixed and swivel fittings. Non-swivel (fixed) eye bolts and non-swivel (fixed) eye nuts, such as those compliant with DIN 580 and DIN 582 standards, are primarily load-rated for axial/vertical lifting only. Using them for angular lifting drastically reduces the Working Load Limit and introduces significant risk. In contrast, our selection of swivel eye bolts and swivel eye nuts (also known as Hoist Rings or Load Rings) is engineered as multi-directional lifting points. This advanced design allows for 360° rotation and up to 180° pivot, maintaining the full WLL even when subjected to angular loads. They offer superior flexibility and safety for complex rigging operations.

Material Grade and Environment: The integrity of the lift depends on the material grade and finish. For extreme loads and demanding environments, we offer Grade 8 High-Capacity Eye Bolts, which provide maximum strength and reliability. For corrosive, humid, or marine-grade applications, our Stainless Steel Eye Bolts and Eye Nuts (often available in A4 specification) provide outstanding resistance to rust and wear, guaranteeing durability across industrial sectors.

Frequently Asked Questions (FAQ)

Can I use a regular (non-swivel) eye bolt for angular lifting?

We strongly advise against using a standard, non-swivel eye bolt for angular (side) loading. Non-swivel fittings are designed and load-rated for vertical (axial) lifts only. Using them at an angle can reduce the stated Working Load Limit (WLL) by up to 70% or more, creating a severe safety risk. For any non-vertical lift, you must use a specialised swivel eye bolt or swivel hoist ring, which is engineered to maintain its WLL under angular stress.

What do DIN 580 and DIN 582 mean for Eye Bolts and Eye Nuts?

DIN refers to the German Institute for Standardisation, and these numbers specify the design and dimensions for common lifting hardware. DIN 580 typically refers to the specification for collared lifting eye bolts, while DIN 582 refers to the specification for lifting eye nuts. Products compliant with these standards are manufactured to strict European specifications, ensuring consistency, reliability, and that the product is suitable for lifting when properly installed and used within its vertical Working Load Limit (WLL).

How do I ensure I am not exceeding the Working Load Limit (WLL) of my lifting eye?

Always refer to the WLL, which is stamped or permanently marked on the body of the eye bolt or eye nut. This rating applies only to a straight-line (axial/vertical) pull unless the fitting is specifically a swivel-type lifting point. If you are using a fixed eye bolt for an angled lift (which should be avoided), you must consult the manufacturer's official de-rating chart and never exceed the reduced capacity. Regular inspection for thread wear or damage is also essential to maintaining the rated capacity.