125Kgs SWL Column Jib Crane c/w Electric Chain Hoist

-88x60.webp)

-88x60.webp)

-88x60.webp)

Key notes for ordering:

Dispatched as a kit with instructions, decide on extras like isolator for electrics, festoon system for elec hoist. Contact us for installation prices. Suppled with certification

Estimated lead time:Manufactured in UK to Order Approx. 2 - 3 Weeks Delivery

Please call us if you need this item sooner

& COLLECT

delivery

DELIVERY

(Call us)

Seen this product cheaper elsewhere?

We will always try to offer this product at the best price. We will do our best to not just match it but to beat it.

Price match

promise

125Kgs SWL Column Jib Crane c/w Electric Chain Hoist

Capacity

125Kgs

Description

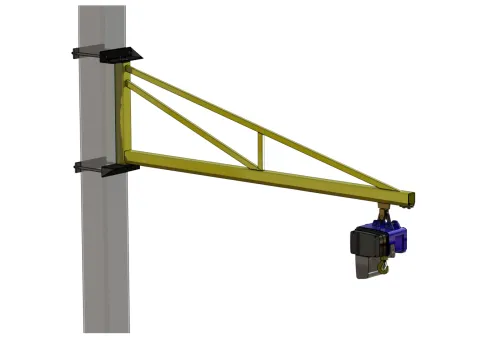

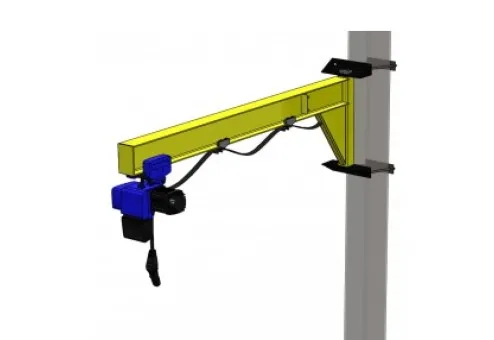

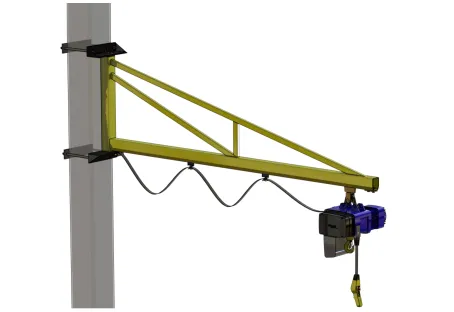

The 125kg SWL Column Jib Crane, complete with an Electric Chain Hoist, is manufactured in the UK. These column-mounted jib cranes come fully equipped with a high-quality Electric Chain Hoist, saving you time by eliminating the need to select a separate hoist. Ideal for situations where you need a crane suspended securely from an existing column, pillar, or stanchion within your building, these cranes are designed for flexibility. The arm can be custom-manufactured to any length between 2m and 6m, and it is designed to swivel (slew).

£549.98 ex VAT

£544.99 ex VAT

£653.99 inc VAT

1 - Adjustable Slew Limits

2 - Slewing Lock

3 - Installation

Related products

-494x340.webp) Festoon System for Overhead Cranes & Hoists

Festoon System for Overhead Cranes & Hoists

FEST SS

C Rail Style Festoon System (Full Kit) including flat form power cable, cable trolleys & track. These simple-to-install lightweight kits provide a safe and economical means of supplying power to overhead hoists, overhead cranes, and most other types of moving machinery that travels along a fixed track. Once fitted eliminates dangerous dangling down cables and looks like a professional install or refit

£124.98 ex VAT

£149.98 inc VAT

125Kgs SWL Column Jib Crane c/w Manual Chain Hoist

125Kgs SWL Column Jib Crane c/w Manual Chain Hoist

CMJC

All our 125Kgs SWL Column Jib Crane c/w Manual Chain Hoist are manufactured in the UK. These Column Mounted/I-Beam Mounted Jib cranes are supplied complete with a quality manual chain hoist, which saves time on selecting which hoist. These column Jib cranes are ideal if you are looking for a crane suspended securely from an existing column, pillar, or stanchion within your building.

£549.98 ex VAT

£659.98 inc VAT

125Kgs SWL Column Mounted Jib Cranes - Under-Braced

125Kgs SWL Column Mounted Jib Cranes - Under-Braced

UBCMJC

125Kgs SWL Column Mounted Jib Cranes - Under-Braced version, manufactured in UK and can be made to bespoke dimensions. Under-braced Jib Cranes are Ideal for use in a factory that needs a Jib crane to be bolted or welded to structural steelwork, pillars, or stanchions.

£898.98 ex VAT

£1,078.78 inc VAT

This Column Mounted Jib Crane is supplied complete with a high-quality Electric Chain Hoist, saving you time on selecting the appropriate hoist to fit the Jib Arm. These cranes are perfect for applications where a crane is suspended securely from an existing column, pillar, or stanchion within your building. The arm can be manufactured to any length between 2m and 6m, and is designed to slew through 180°, offering a wide working area.

Please note that anti-slip measures must be implemented to prevent the Jib Arm from slipping or moving down the column it is attached to. The arm comes with a pre-fitted trolley, making it easy to connect your hoist, spring balancer, or vacuum lifter.

Simplified Package – All-In-One Solution

To save you time and stress, we’ve bundled the Jib Crane, a high-quality 400-volt Electric Chain Hoist, and an integral fitted Push Travel Trolley into one convenient package. All you need to do is select the required height of lift for the manual hoist to suit your Jib Crane's working height.

Full Electric Supply Kit

If added to your order, our full Electric Supply Kit includes everything required for the installation of both the Jib Crane and the Hoist. The kit contains the main isolator, a supply cable for the hoist (cut to the appropriate length for the arm purchased), and cable trolleys to keep everything neat and tidy.

| Model | SWL | Overall Height Of Arm | Trolley Depth | Arm Length (Radius of reach) | Total Weight |

| CMJC125R2 | 125Kgs | 400mm | 65mm | 2,000mm (2m) | 45Kg |

| WMJC125R3 | 125Kgs | 500mm | 77mm | 3,000mm (3m) | 49Kgs |

| WMJC125R4 | 125Kgs | 600mm | 77mm | 4,000mm (4m) | 60Kgs |

| WMJC125R5 | 125Kgs | 900mm | 77mm | 5,000mm (5m) | 86Kgs |

| WMJC125R6 | 125Kgs | 1000mm | 77mm | 6,000mm (6m) | 99Kgs |

Why Choose a 125kg SWL Column Jib Crane with Electric Chain Hoist?

There are many advantages to purchasing a Column Mounted Jib Crane. These cranes are extremely versatile within the factory, speeding up the lifting and moving of components from presses or workbenches, as well as loading and unloading lorries. They are ideal for lifting heavy objects such as granite, timber, or steel.

Column Jib Cranes consist of two main parts: the arm and the set of brackets used to attach the crane to existing steelwork. These simple manual jib cranes have few components to maintain, making them highly reliable. Their straightforward design reduces the risk of breakdowns, which means no loss of production time.

Easy To Install

The 125kg SWL Column Jib Crane with Electric Chain Hoist is easy to install. It simply bolts onto existing columns, pillars, stanchions, or any suitable structural steelwork. After ensuring your column is suitable for the jib crane, you can select the model you need from the dropdown menus, and we will arrange to manufacture and dispatch the crane directly to your site for the required delivery date.

Once the crane arrives on site, it can be secured to the steelwork (ensure anti-slip measures are in place to prevent the crane from sliding down the support column). At Ultimate Lifting Solutions, we offer full installation services by our highly trained engineers or can handle just the commissioning and load testing, depending on your needs.

Due to the simple design, these cranes are cost-effective to both purchase and maintain compared to other crane types. Under normal working conditions, they only require an industry-standard annual service. We at Ultimate Lifting Solutions offer various maintenance and service packages to meet your requirements.

How Does the 125kg SWL Column Jib Crane with Electric Chain Hoist Work?

A standard swing jib crane has two main parts: the arm and mounting brackets. The arm rotates from left to right, with a standard swing angle of 180°. For all our swing jibs up to 1,000kg, the arm will rotate smoothly without the need for powered assistance, helping to keep costs down.

The arm on our jib cranes is equipped with an integral push travel trolley that moves along the full length of the arm. This trolley provides the freedom and flexibility to reach corners of your factory with ease.

What Else is Required for the Column Jib Crane?

Once your swing jib is fitted, you will need a hoist, vacuum lifter, or spring/tool balancer. These fit easily onto the trolley already supplied with the jib crane arm. You will just need to decide which hoist best suits your needs.

To keep costs down, a manual hoist is the most affordable option. However, manual hoists are slower and require assistance to operate. For larger items, the hoist chain may not reach. The second, and more efficient, option is an electric hoist. Electric hoists allow you to lift and lower components quickly, reducing production time and paying for themselves through time saved.

Installation

As mentioned, the jib crane is easy to install. Once the crane and hoist are in place, all that remains is commissioning, testing, and signing off the crane as safe to use. We are happy for customers to install the crane themselves using the instructions provided or arrange their own installation team. However, if time is tight, let us help you. We offer a complete installation service, including crane and hoist installation, commissioning, testing, and ensuring everything is working correctly and safely before we leave the site.

125kg SWL Column Jib Crane with Electric Chain Hoist

All of our manufactured Jib Cranes feature the following:

- Duty Classification: A3, according to BS 733: 1990

- Lubrication-Free Design: The pivot bushes are made of acetal, eliminating the need for lubrication. The trolleys' running surfaces are also lubrication-free.

- Manual Slewing and Trolley Travel Operation: Easy to operate with minimal maintenance required.

- Clutch-Controlled Slewing Mechanism: The slewing mechanism can be tightened or loosened to control the pivoting resistance of the arm.

- Base Construction: Fully welded to the column. In most cases, this removes the need for an oversized load-spreading plate or an anchor frame set into concrete, resulting in quicker and more cost-effective installation.

Key Features of Our UK-Manufactured Jib Cranes:

- SWL: 125kg

- Arm Length: 2m to 6m

- Slew Angle: 180-degree manual slew

- Trolley: Equipped with an integrated push travel trolley, ideal for suspending hoists, vacuum lifters, and tool balancers

- Fast Delivery: We aim to deliver all our Swing Jibs within 2 to 3 weeks

Optional Extras:

- Adjustable Slewing Limits: To reduce the swing arc

- Slewing Lock: To fix the arm in a specific position

- Electrical Isolator: Required when using an electric hoist in conjunction with the Jib Arm

- Full Electric Kit: Includes everything needed to operate the Electric Hoist (Isolator, Flatform Supply Cable, Cable Runners)

- Pin Fitting Kit: Can be supplied to enable the pin to be fitted from below

The 125kg SWL Column Jib Crane with Electric Chain Hoist generally requires minimal service or maintenance. However, operators should regularly observe the overall condition of the jib and the hoist. Any faults should be reported immediately.

More importantly, to ensure the jib and hoist run at maximum efficiency and remain compliant with UK regulations regarding LOLER inspections as set out by the HSE, both the jib and hoist should undergo a scheduled maintenance service every 12 months. This service should be performed by qualified service engineers.

If you would like to learn more about crane servicing and general maintenance, please feel free to contact us. Our team of qualified engineers is available and happy to provide a quote for all your crane servicing needs.

More products from category:

Lifting Equipment

110 Volt Scaffold Hoist 200kg Capacity

110 Volt Scaffold Hoist 200kg Capacity

DM200i

The 110-volt Scaffold Hoist has a 200 kg capacity and comes with a swivel bracket for direct attachment to scaffold tubes. It features a lifting height of 25 meters and a lifting speed of 25 meters per minute. This high-quality hoist is designed for professional builders and heavy-duty lifting. The DM200I is quickly becoming a customer favorite and one of our top-selling products.

£794.98 ex VAT

£953.98 inc VAT

360 Degree Column Jib Crane 250Kg Capacity

360 Degree Column Jib Crane 250Kg Capacity

RJC

360 Degree Column Jib Crane offers total flexibility within the workplace. The crane arm has full rotation around the main upright column, providing a complete circular lifting aid of up to 6m. Overall column height can be manufactured up to 6m Tall

£1,698.98 ex VAT

£2,038.78 inc VAT

BlueLink Bluetooth Digital Dynamometer

BlueLink Bluetooth Digital Dynamometer

BLD6T5

£1,069.98 ex VAT

£1,283.98 inc VAT

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar Battery 1000Kgs Powered Chain hoist

CM BatteryStar

The CM BatteryStar is the brand new Battery Powered Chain hoist that has been built with industry-leading technology from Columbus McKinnon and Milwaukee Tool. Designed for portability and easy installation, the BatteryStar can have you lifting in minutes. Supplied without Battery/Charger as standard

£2,498.98 ex VAT

£2,998.78 inc VAT

SUBSCRIBE FOR THE LATEST NEWS & SPECIAL OFFERS

Sign up here to get the latest news, updates and special offers delivered to your inbox.

-454x312.webp)

-454x312.webp)

-454x312.webp)

Add to cart

Add to cart Add to quote

Add to quote